Production capacity

Over 700 tonnes processed every year

SERVICE CYCLE

From the receipt of the order to the delivery of the moulded product the step is short. The production planning and the control of the progress through dedicated software allow to respect the required lead times. The three-shift processing combined with a large and diversified fleet of machines make it easy to deal with emergencies and unforeseen events, thus ensuring compliance with the agreed deadlines.

PRODUCTION CONTROL

The planning and control of progress is managed through dedicated software (ALS Arburg). The complete interconnection between the planning office and the individual machines in the production department guarantees instantaneous data on progress and any problems, allowing you to better manage the subsequent phases of control, post-processing and packaging of products, until delivery on time. To guarantee consistency between the different productions, the moulding parameters are saved in back-up on a central server and during the set-up phase they are recalled by the operator at the press, reducing the variables that could compromise the repeatability of the process. The complete production data are periodically analysed to plan targeted interventions where necessary and thus ensure maximum efficiency.

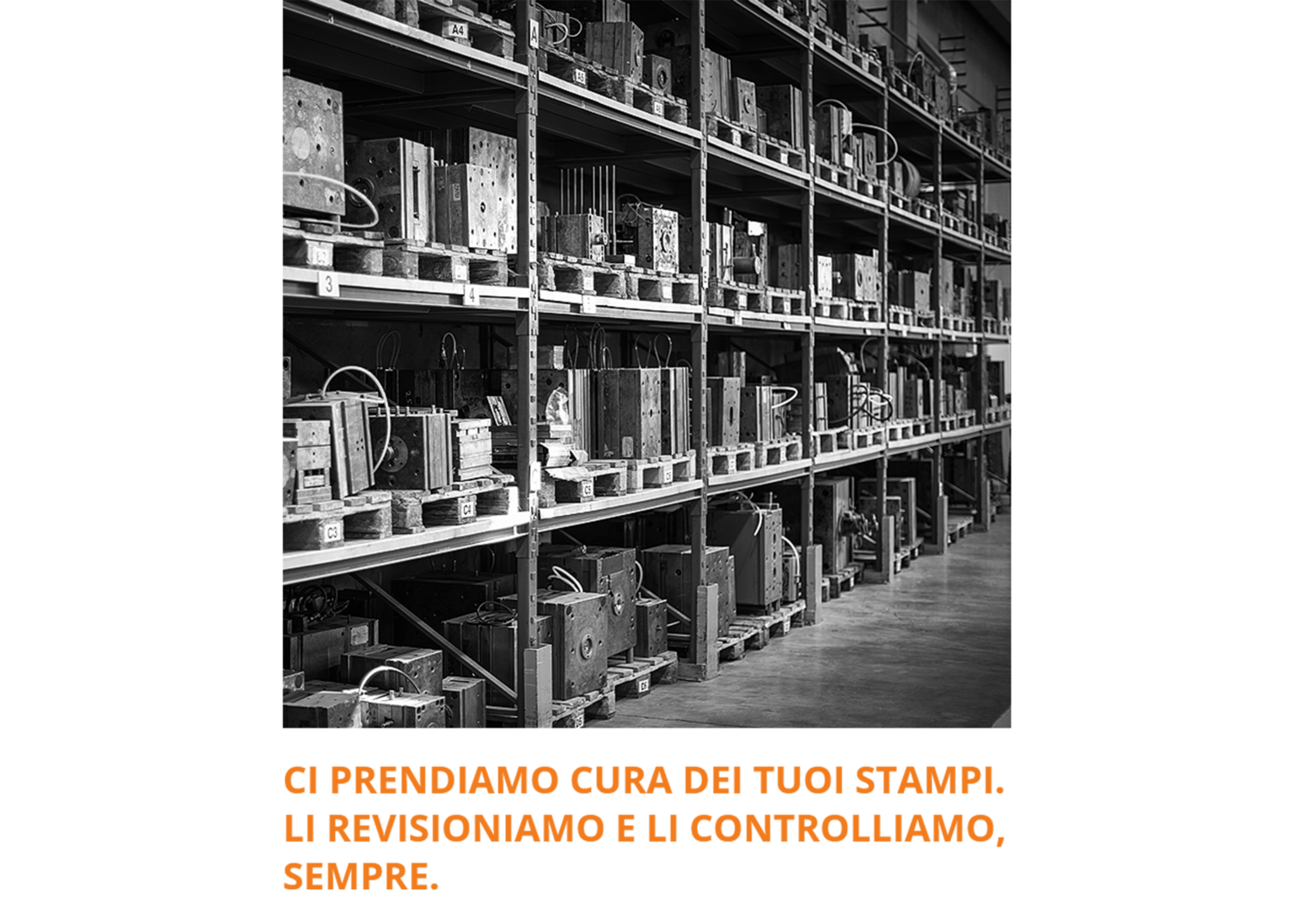

MOULD AND EQUIPMENT MANAGEMENT

All equipment is thoroughly cleaned and maintained after each processing cycle. The management of dedicated scheduled maintenance plans for the verification and replacement of critical parts allows to minimize the need for extraordinary maintenance and resulting periods of stop. An internal workshop and the collaboration with selected external partners allow to better manage any need for maintenance or modification of equipment.

Informazioni?

Domande/Richeste?